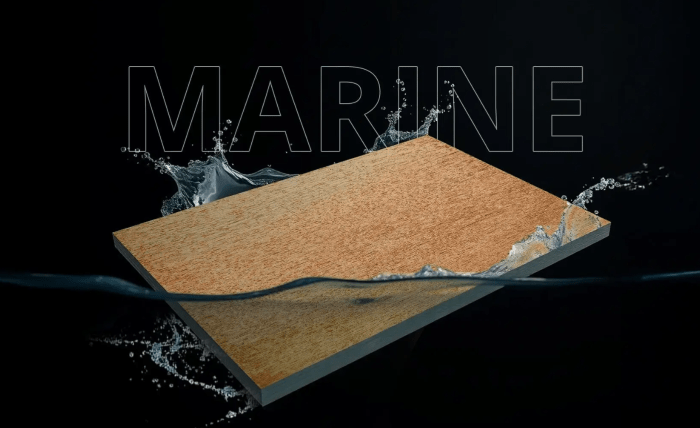

Marine plywood sheets are renowned for their durability, water resistance, and versatility, making them a go-to material for a variety of applications. Despite their widespread use, several misconceptions surround marine plywood, leading to confusion among consumers. This article delves into and debunks five common myths about marine plywood sheets to provide clarity and insight.

Marine Plywood is Completely Waterproof

The Truth: While marine plywood is highly resistant to water, it is not entirely waterproof. Its superior moisture resistance is due to the high-quality veneers and waterproof adhesives used in its construction. However, prolonged exposure to standing water or submersion can still lead to damage over time.

Debunking:

- Marine plywood can endure high humidity and occasional splashes but requires proper sealing for long-term water resistance.

- Applying waterproof coatings or sealants enhances its durability in wet environments.

- Without additional protection, even marine plywood can deteriorate when continuously exposed to water.

Marine Plywood is Only for Marine Applications

The Truth: Although marine plywood is named for its suitability in marine environments, its applications extend far beyond boats and docks.

Debunking:

- It’s ideal for outdoor furniture, kitchen cabinets, and bathroom installations due to its moisture resistance.

- Creative uses include decorative wall panels, flooring, and customized home décor projects.

- Its versatility makes it a popular choice for both indoor and outdoor applications, proving that marine plywood is far more than a niche product.

All Marine Plywood is of the Same Quality

The Truth: Not all plywood sheets are created equal. The quality can vary significantly depending on the type of wood, adhesive, and manufacturing standards.

Debunking:

- High-quality marine plywood adheres to standards like BS 1088 or IS 710, ensuring durability and performance.

- Low-grade plywood may not meet these standards, leading to compromised strength and water resistance.

- Always check certifications and source your plywood from reputable suppliers to ensure you’re getting a product that meets your project’s demands.

Marine Plywood is Too Expensive

The Truth: Marine plywood is more expensive than standard plywood, but its cost reflects its superior quality and longevity. In the long run, it can be a cost-effective choice.

Debunking:

- Its durability reduces the need for frequent repairs or replacements, saving money over time.

- For specific projects requiring water resistance, investing in marine plywood eliminates the risk of material failure and additional costs.

- While the upfront cost may be higher, the long-term value of marine plywood often outweighs the initial investment.

Marine Plywood Doesn’t Require Maintenance

The Truth: While marine plywood is durable and resilient, it still requires proper care to maximize its lifespan.

Debunking:

- Regular cleaning and sealing help protect it from environmental damage, such as moisture and UV exposure.

- Inspecting for signs of wear, such as cracks or delamination, allows for timely repairs and prevents further deterioration.

- Proper maintenance ensures that marine plywood performs optimally for decades, making it a reliable and long-lasting material.

Conclusion

Marine plywood sheets are an exceptional material for a wide range of applications, but misconceptions about their properties and uses can lead to unrealistic expectations. By understanding the facts and debunking these myths, you can make informed decisions and get the most out of marine plywood. Investing in high-quality marine plywood and providing proper care ensures durability and long-term satisfaction. Whether for marine environments or creative home projects, marine plywood’s versatility and resilience make it a standout choice.